Front Cylinders

The two small cylinders below the timer will eventually house all the keylock switches and LED indicators for the Mod. They mirror the shape of the recessed reservoir, and the strapping bands around them fit with the ones around the main cylinder. As with making the case in several sections, I wanted to avoid the look of a boring single cylinder with switches just set into the side.The timer, small cylinders and (eventually) keypad, will end up looking like a single unit that has been strapped to the body of the main cylinder. These are still quite a way from completion, with a lot of wiring, switches and indicators to be installed. Also, the keypad and housing will end up filling up the remainder of the empty space below the timer. Once it's all together and illuminated, it should look very menacing indeed!

I started with a 1m length of 50mm (2") diameter stainless steel handrailing. Before I could cut the two lengths I needed, I cut a short section off the end in my mitre box to ensure it was squared.

I measured, marked and cut two identical lengths of pipe. You can see me checking the fit of a couple of the end caps I planned to use.

Once cut, I wrapped each piece in masking tape to prevent scratches, and provide a surface to mark a couple of parallel centre-lines. I wanted to make the cylinders look like they are recessed into the case, in a similar fashion to the reservoir. This would also ensure they didn't protrude too far from the body of the case and dominate the timer. It meant I would have to cut an identical section out of each cylinder. Centre-lines gave a guide...

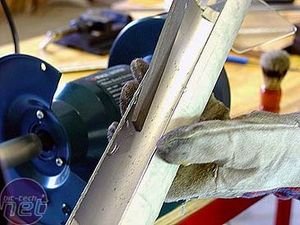

...and careful hacksawing gave me a nice straight line. I could only get half way, though, as the saw would have started cutting out the other side of the pipe.

I turned each piece around and cut from the opposite end. Rinse and repeat. 4 cuts in total...

...took a section out of the pipe. All the practice I had hacksawing acrylic on my last mod really paid off, as I was able to get dead straight lines. As I'd only cut to within 1mm off the marked lines, I lightly ran each section back and forth across the bench grinder to smooth the cuts and take them up to the lines.

I filed off the burrs from the grinder...

...and when done, had two matching sections of pipe. Now the fun began...

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.